Thermal Imaging

Thermography

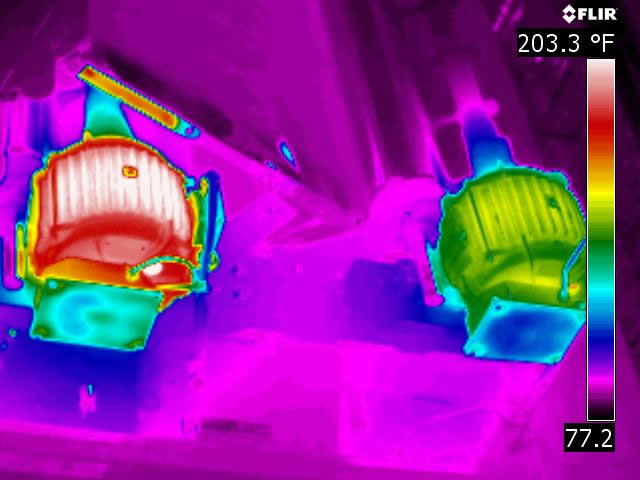

Heat is often an early symptom of equipment damage or malfunction, making it a key performance parameter monitored in predictive maintenance (PdM) programs.

Technicians who practice infrared predictive maintenance regularly check the temperature of critical equipment, allowing them to track operating conditions over time and quickly identify unusual readings for further inspection.

By monitoring equipment performance and scheduling maintenance when needed, these facilities reduce the likelihood of unplanned downtime due to equipment failure, spend less on “reactive” maintenance fees and equipment repair costs, extend the lifespan of machine assets, and further maximize maintenance and production.

Here’s the trick: To actually save money, predictive maintenance should not create excessive additional maintenance efforts. The goal is to transition maintenance resources away from emergency repairs and into scheduled inspections of key equipment.